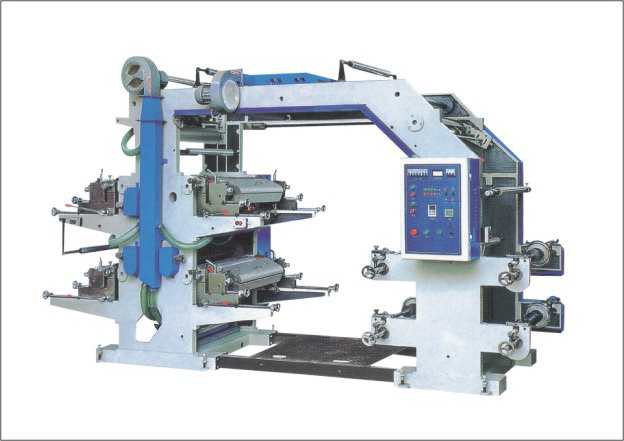

Fully automatic Non woven box type bag making machine

This machine is suitable for printing such packing materials as polyethylene, polypro-pylene plastic bag, glass paper and roll paper. etc.And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Features

1. Simple, soft start, accurate color register.

2. Automatic counting the number of print controller can be arbitrarily set to the number of automatic shutdown.

3. Knurled cylinder with ink, ink evenly.

4. Reliable drying system coordinated with high-speed dynamic switch, automatic shutdown circuit.

5. With print quality, energy consumption, complete automatic control, stable performance, easy operation and maintenance. Photosensitive resin is used as a soft version of the layout of the printed press. "Commonly known as aniline printing machine (water-based paint)", suitable for printing non-woven polyethylene, polypropylene plastic bag, cellophane, Web and other packaging materials.

Technical specification

| Type | HB4-1000 | HB4-1200 | HB4-1400 | HB4-1600 |

|---|---|---|---|---|

| Maximum width of printed materials | 1000mm | 1200mm | 1400mm | 1600mm |

| Printing maximum width | 960mm | 1160mm | 1360mm | 1560mm |

| Length range of printed materials | 200-800mm | 200-800mm | 200-800mm | 200-800mm |

| Coil diameter | 800mm | 1000mm | 1200mm | 1400mm |

| Printing speed | 5-50m/min | 5-50m/min | 5-50m/min | 5-50m/min |

| Plate thickness | 3.94mm | 3.94mm | 3.94mm | 3.94mm |

| Total power | 15kw | 17kw | 19kw | 21kw |

| Dimensions (L * W * H) | 3580 * 2100 * 2450mm | 3580 * 2300 * 2450mm | 3580 * 2500 * 2450mm | 3580 * 2700 * 2450mm |